Life Science, challenging sensor applications

Miniaturization is a highly relevant trend in medical and lab technology. Increasing automation, constant object size reduction and increasing accuracy requirements lead to a higher integration degree. Driving applications are lab-on-a-chip, portable units or even invasive components like micropumps or catheters with sensor functions. Therefore sensor assemblies have to become smaller and smaller. Extremely low energy consumption, which enables long battery life, is another important factor for functional reliability.

Conventional photoelectric sensors come to their limits because of size and optical performance data of the components which are used. For example, most of the LEDs are manufactured by the major semiconductor manufacturers for lighting purposes. Instead of miniaturization and optical precision, the focus is on output power and illuminance. Size, design and connection method are simply defined according to mainstream needs of the mass market. Fiber optics, often the only alternative in terms of size have natural physical and photoelectric disadvantages in life science applications.

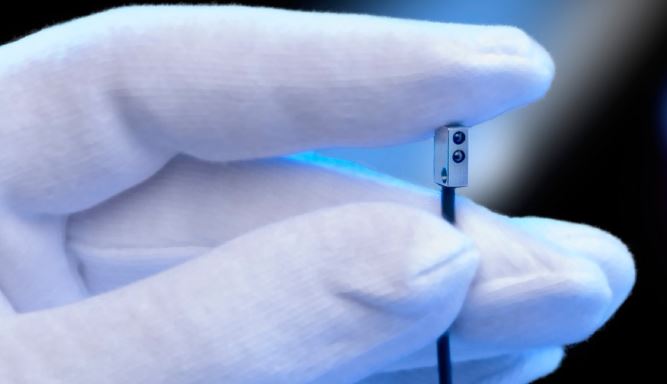

Foundation: Photoelectric precision components

Rather than sourcing standard mainstream photoelectric elements Balluff (with group company Balluff STM) produces photoelectric miniature components with an own manufacturing process. Their optical characteristics exceed those of commercially available components. Particularly small precision LEDs, photo diodes, photo transistors and complete laser modules are produced with a special process. Due to the high optical quality, they can also be integrated directly into exceptionally compact device designs. Without additional lenses or apertures. the miniature opto-elements are built on substrates made of FR4 or ceramic. The shape and pin layout can be quickly adapted to the customer’s design needs. Typical applications are pinpoint sensor functions in medical, laboratory and analytical measurement technology, e.g. Flow monitoring in microfluidic structures, bubble detection in miniaturized pumps, sensor measuring heads, etc. With the selection of specific wavelengths the optoelectronic properties are adapted to the required physical and biological / chemical effects. Absorption or fluorescence can be optimally used , such as spot size, opening angle or intensity distribution can be determined to achieve best sensing performance.

Example 1: Precise detection of liquids

Refraction and attenuation of light are the physical effects that can be used in the optical detection of liquids. What is important here is the precise positioning of the transmitter and receiver elements and the optimal selection of the light wavelength, e.g. to use the greatest possible measuring effect when evaluating the optical attenuation of water. The reliable use of light refraction requires particularly precise guidance of the light beam. These miniature photoelectric sensors with a very fine light beam enable high measuring precision to be applied even with thin tubes and hoses with large signal strokes and the resulting functional reserve. They are simply clamped onto the hose. The signals are evaluated with a suitable standard amplifier or with customer-specific evaluation electronics. Even with small hose diameters, the sensors deliver signal strokes with high reproducibility. Their application ranges from exact volume measurement to reliable detection of microbubbles.

Example 2: Reliable detection of transparent objects

Checking the presence of transparent bodies made of injection molded plastics or glass is often surprisingly difficult. Interfering effects often occur at the interfaces, e.g. Total reflection, scattering or light conduction. The optical detection of transparent surfaces, regardless of whether they are flat or curved, requires a very high quality of the light beam that is precisely tailored to the respective query situation. Application example: magazined substrate carriers. Due to their tight packing and the very different quality of the edges, unwanted reflections or deflection effects can occur. Even minor changes in the geometry can have a drastic impact on the reliability of the entire acquisition. Tailor-made, customer-specific optical sensors with a parallel light beam, with a small diameter and without scattered light meet these detection requirements.

Example 3: Microfluidic channels and capillaries sensing

The detection of transparent liquids in microchannels or capillaries is, due to the given dimensions, an optical challenge. The slight differences in the refractive indices of the substances involved make optical detection a special task. Specialized miniature photo sensors are suitable for these applications because of their minimal size and their precision optics. Application example: Lab-on-a-Chip. The light beams from special sensors can be precisely aligned on capillaries or microfluidic structures. By using a special wavelength, for which water has an increased absorption property, a reliable signal is produced even with a minimal channel size. Application example: Detection of micro bubbles in capillary tubes. The micro-bubble sensor illuminates the entire interior of the hose with its precision optics so evenly that even microscopic bubbles that are significantly smaller than the inside diameter can be reliably detected. Upon request application know-how when looking for an optimized solution can be provided

For further information about Automation in Life Science:

Life Science Sensor Applications

[…] Miniaturization plays an important role in life sciences and laboratory automation. What can miniaturization do in these applications? Here is another interesting blog post: https://www.innovating-automation.blog/automation-in-life-science/. […]

[…] optoelectronic sensors, which manage the balancing act between standardized production and specialized areas of […]

[…] media).Examples can be found in the following blog posts: Application Spotlight: Wafer Mapping, Automation in Life Science, Specialized Sensors for Lab Automation, Fiber Optics vs. Micromote, Custom Sensors: Let your specs […]