Life supporting Medical Equipment receives a lot of attention since the Corona pandemic

In times of the Coronavirus pandemic and the related COVID-19 it is worth to have a closer look on medical equipment. Especially on the devices that save patients‘ lives. During the past months we all have seen those pictures out of the hospitals. Patients are connected to different „machines“ that we usually do not see or deal with.

In this article I describe different medical equipment and its purpose. Also I provide an overview of what automation and sensors can do. Ultimately they support the incredible efforts of the people working in the medical sector. Consequently, in modern intensive care units and operating theaters there are many sensors on the medical equipment. Maybe even more than you might think.

Contents

1. Ventilators to maintain respiration

Many surgeries are only possible with respirators. The reason is, that under general anaesthetic respiration ceases, and ventilation sustains life. Besides the use in surgeries it also supports patients with respiratory system issues. This may happen as a consequence of COVID-19.

COVID-19 is short for Coronavirus Desease 2019. The official name of the virus is "SARS CoV 2" (Severe Acute Respiratory Syndrome Coronavirus 2).

So the name already tells you why ventilators became such an important device in 2020. Ventilator settings must be synchronized with the patients lungs and respiration. Magnetically coded position sensors are a perfect fit to control the motion of the pump. Finally, the compact design allows integration into the ventilator.

2. Cardiopulmonary Bypass machines

These machines enable open heart surgeries, such as coronary artery bypass surgeries. During the surgery the heart stands still. Then the heart lung machine takes over the key functions: pumping (circulating) and oxygenating blood. It is key to monitor fill levels of blood in the venous reservoir. Detecting blood is critical due to its characteristics. Special capacitive sensors detect min and max fill level of the reservoir. They offer versatility in many fill level detection applications.

heart lung machine, fill level sensor

3. Infusion pumps for automated medication

Infusion Pumps play an important role in hospital medication. Especially in ICUs (intensive care units) patients with severe deseases are under constant observation. Infusions pumps ensure the correct medication at the right time in the right amount.

Older Infusion pumps utilize end of stroke sensors for max and min position. New generations use continuously measuring sensors that offer not only the end positions. Even more they provide continuous position feedback and velocity information.

Magnetic tape systems allow accurate position feedback. Additionally they are very compact and can therefore be intergrated in infusions pumps. Infusions pumps save lives but they also can be devastating in case of wrong medication, flow or quantity. A safety version of a position feedback sensor increases the security of operations. Additionally LED based photoelectric sensors detect even smallest amounts of liquids or microbubbles.

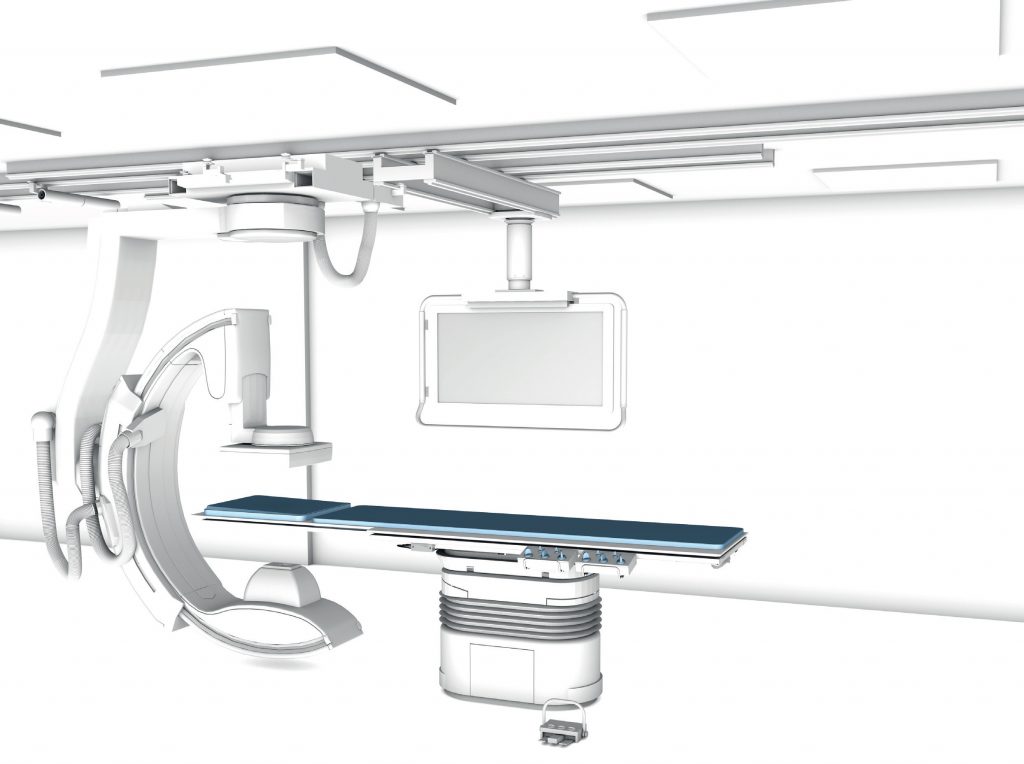

4. Surgery tables for accurate treatment

Ventilation and blood circulation is under control. Now I focus on another key equipment in operating theaters: surgery tables. To get best access to the patient these tables can be moved in all axes. Not only in operating theaters but also in other disciplines of medical treatment, special tables help doctors.

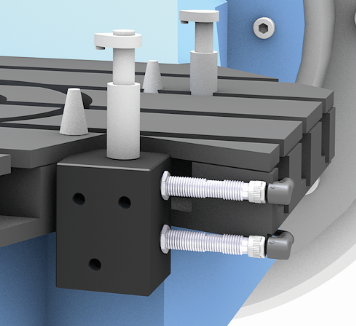

In radiology these tables move along six axes. Therefore motion bases (6DOF or hexapods) under the actual table position the patient for precise therapy. Linear transducers deliver position feedback in hydraulically actuated tables. Independent from the technology for motion, inclinometers also deliver accurate position feedback.

5. Dialyzers to improve health conditions of diabetics

This is not a typical instrument for intensive care units, but still life saving. People with severe kidney failures need dialysis. This means that a machine takes over the function of the kidneys: filtering and purifying blood. Therefore dialysates are required. Blood is pumped through the actual dialyzer and is cleaned with the help of dialysis solutions. So, sensors measure the fill level of the fresh and used dialysate. Capacitive sensors detect liquids through tank walls.

Last word

Miniaturization plays an important role in life sciences and laboratory automation. What can miniaturization do in these applications? Here is another interesting blog post: https://www.innovating-automation.blog/automation-in-life-science/.

It is all about improving health with automation

These are just some examples of what automation companies can do in the life sciences industry to improve the equipment used in operating theaters, intensive care units or in nephrology. In the end it is all about contributing to improving patients health condition.