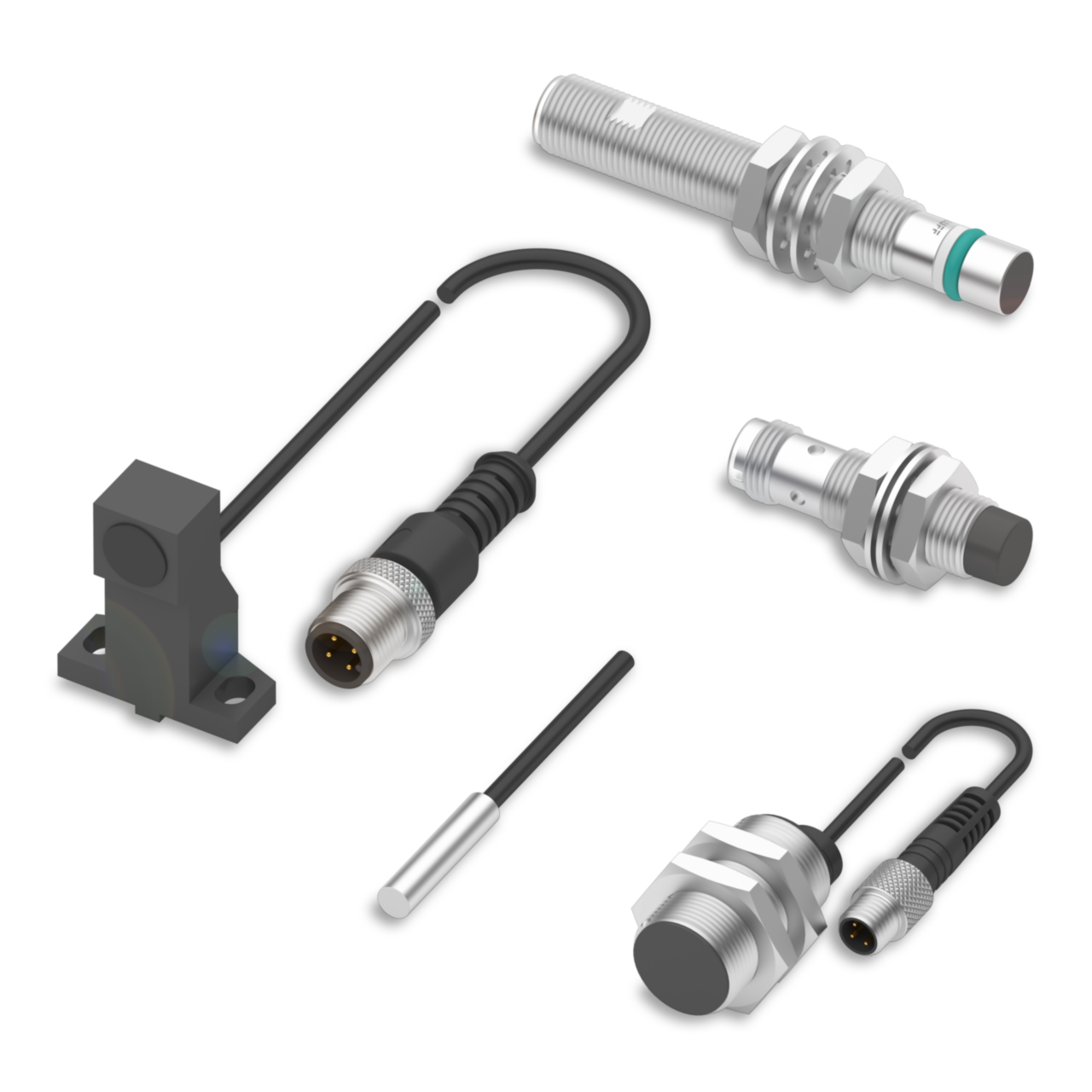

Inductive distance sensors

Inductive sensors

Available in:

8 Series

Our BAW inductive distance sensors measure various positions, distances, and can differentiate between material variants. They work without making contact, and so remain distinguished by a long service life free from wear.

The included teach function has an adjustable linearity range. This enables quick commissioning during initial installation and ensures short downtimes when replacing sensors.

The multiplicity of available configurations allows the inductive distance sensors to be easily integrated into any application. Important applications include monitoring movements in joining, pressing, or clamping equipment used for mechanical engineering or detecting axle imbalances and expansions. The inductive distance sensors supply an absolute analog voltage, current, or IO-Link signal.

Features

- Compact, solid and reliable

- Non-contacting and thus free from wear

- Absolute measuring principle

- Measurement range from 0.2 to 50 mm, also teachable

- Quick response time, high reproducibility, and linearity

- Broad temperature range, minimal temperature drift

- Simple application via analog interfaces and IO-Link

8 Series

| Series | Style Housing | Range/measuring range | Interface | Connection type | Installation | Actions |

|---|---|---|---|---|---|---|

BAW G6Cylindrical miniature version without thread |

D6.5 | 2 mm | Analog, voltage, Analog, temperature | Cable, Cable with connector | for flush mounting | |

BAW MCylindrical version with metric thread |

M30x1.5, M8x1, M12x1, M18x1 | 16 mm | IO-Link, Analog, voltage, Analog, temperature, Analog, current | Cable, Cable with connector, Connector | for flush mounting, non-flush, quasi-flush | |

BAW QSquare version made of plastic |

block style | 50 mm | Analog, voltage | Connector | non-flush | |

BAW R14Cubic version with through holes |

block style | 15 mm | Analog, voltage | Cable with connector | non-flush | |

BAW R3Cubic compact version with through-holes for flush installation |

block style | 4 mm | Analog, voltage | Cable, Cable with connector | for flush mounting | |

BAW R6Cubic version with through-holes for flush installation |

block style | 2 mm | Analog, voltage | Cable, Connector | for flush mounting | |

BAW Z1Cuboid version for non-flush installation |

block style | 5 mm | Analog, voltage, Analog, temperature | Cable | non-flush | |

BAW Z8Cylindrical version for flush installation |

M12x1 | 2 mm | Analog, voltage | Connector | for flush mounting |

Edit columns

Please select which columns should be displayed.

Products

Products