- Life Science

- Semiconductor Industry

- Steel and Metallurgical Industry

- Drive Technology

- Metalworking

- Mobile Equipment

- Sensor and networking excellence for Packaging, Food, Beverage, Pharma, and Personal Care industries

- Advancing battery manufacturing automation: achieving superior efficiency and quality

- Automobile industry and suppliers

- Fluid Power Technology

- Plastic Industry

- Intralogistics automation: improve efficiency and throughput

- Energy Production

- White goods

- Electronics industry

- Tire Industry

- Traffic Engineering

Life Science

Precision Sensors for Medical and Laboratory applications

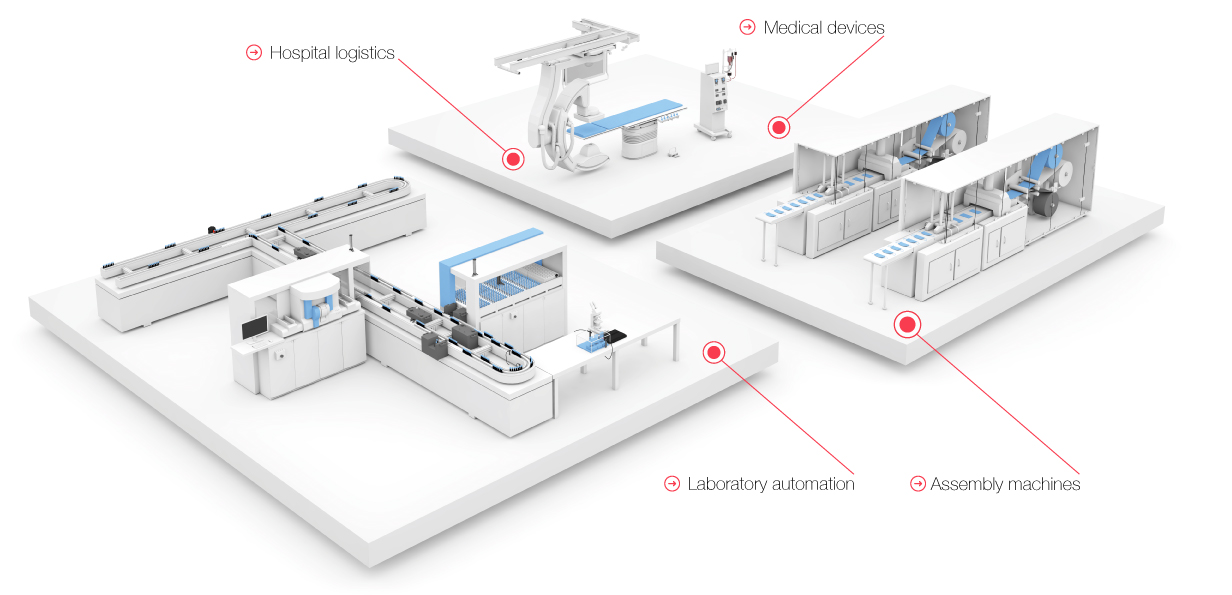

Life science applications require high reliability, minimal measurement tolerances, and small housings. Flexible integration of sensor technology into the system is also important. Balluff offers you a full-range of products and system solutions tailored to individual tasks for laboratory automation, medical technology and hospital logistics.

Whether you need housing modifications, modular systems, integrated housings or technologies in special housings, Balluff is your partner for your special requirements. Contact us to discuss your request.

The products listed here are "standard products" or "modified standard products".

When using these products as components in laboratory or medical equipment, the usability of these products must be checked and qualified by the laboratory/medical equipment manufacturer on his own responsibility.

Before construction, installation and commissioning, please observe the data sheet/operating instructions of the product.

Assembly Machines: Efficient and productive with high quality

Today, modern, application-optimized assembly machines are used for the precise and error-free assembly of medical technology components. With Balluff, you can successfully implement such intelligent production and smart manufacturing. Our sensors and interface components make a critical contribution to the fact that the reliability of automated assembly processes can be optimized further and further and that assembly is better and faster than by human hand.

Laboratory automation: At the core of your processes

Automated laboratory technology for transporting and processing samples in very confined spaces is essential. And it must work in perfect interaction between optical and other sensor technology, miniaturized electronics and precision mechanical components. Progress cannot be stopped in this classic application field of mechatronics. All the more important that Balluff provides you with optimal solutions for a wide range of application in laboratory automation. Whether you want to detect and track objects or focus on efficient liquid handling, our sensors will get you ahead – as important components of automated sample feeding and removal, as well as the dosing of sample material, or analysis liquids.

Medical devices: Innovative in the interest of patients

Medical devices are expensive capital goods whose reliability and precision must be ensured even after years of use. Non-contact and wear-free sensor components enable technical equipment to meet the high demands on usage times and service life in healthcare. Another Balluff strength pays off as well: Thanks to miniaturized design, decisive advantages can be achieved in the dimension of the overall system.

Hospital logistics: Manage Efficiently, Economically

In the wake of new regulations on medical devices, you as a hospital should think about the increased digitization of logistical processes. By moving away from manual documentation, you can tap into long-term cost-cutting potential and reduce the influence of human error – especially in standardized processes. With optical barcode or data matrix scanners and RFID systems, you not only ensure traceability for medical devices, but also optimize processes and instrument use in the direction of Hospital 4.0 and digitization.

Optimal Utilization of Medical Devices

Central sterilization, which performs and documents the complete hygiene cycle of instruments in the hospital, can be made more efficient with automated identification solutions. RFID not only eliminates time-consuming and error-prone manual workflows but also allows for optimal utilization. Thanks to the continuous documentation of all processes in real time between the central sterilization department, the warehouse and the operating room (OR), every operation can be reliably traced. And with a unique identifier, you always know where your inventory is currently being used. Our data carriers are attached hygienically and securely to instruments, trolleys and container trays. But that‘s not all. In addition to RFID solutions, Balluff also offers optical scanners with which you can record bar codes and data matrix codes.

Benefits

Medical equipment optimally utilized

Instruments immediately at hand

Optimized hygiene cycle increases productivity

Efficient warehousing saves multiple storage of instruments and thus costs

Downloads

-

Industry brochure life science – medical and laboratory applications

Products

Products