In order to significantly increase the efficiency and effectiveness of machines and systems, much more information is required from the machine level about the status of the components and the status of the machines themselves, as well as more functionality in individual components.

One of these additional smart sensor functions, which all SAMS components provide, is the integrated logic function.

Read about the basics of the SAMS Smart Automation and Monitoring System in this post and find also more about SAMS Smart Sensors on our Balluff Website.

What are Logic-Blocks in SAMS Smart Automation and Monitoring components?

With the help of this logic function, a wide variety of signals and states within a sensor can be linked together to form new information without having to use a higher-level intelligence such as a PLC control system. The links are configured directly in the component, i.e. the sensor, the RFID read/write head, the encoder or any other device belonging to the SAMS component family. No programming tools or even programming knowledge are required for this, the links are defined via integrated parameter settings in the components.

Execution

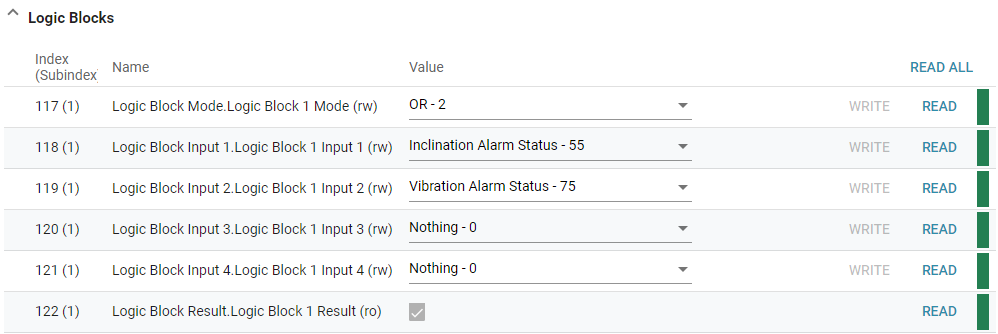

In each SAMS component up to 4 so-called LOGIC blocks are available, within each up to 4 signals can be linked together to form a new result.

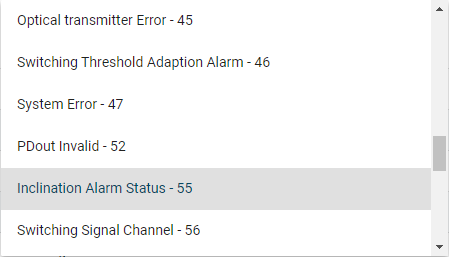

The type of each function can be selected between OR, AND, NOR or XOR. The signals to be linked are selected from a list of all binary signals available within the device.

For example, switching states, alarm states such as inclination, vibration or temperature alarms, or even internal states such as overload or signal quality can be linked with each other.

The result of each link is available as “Logic Block Result” and can be processed further.

Applications

Using the logic functions, a wide variety of signals and information can now be linked together without having to use additional intelligence.

Advantages of the SAMS Function Logik-Blocks

- In addition, the process data length can be reduced by not having to map each individual piece of information as a bit state, but only the result of the individual function. This saves data memory at the Control Level.

- The communication load can also be reduced in this way, since not every single piece of information must be transmitted, but only the result of the function.

- This in turn leads to speed advantages in communication since the overall load can be reduced.

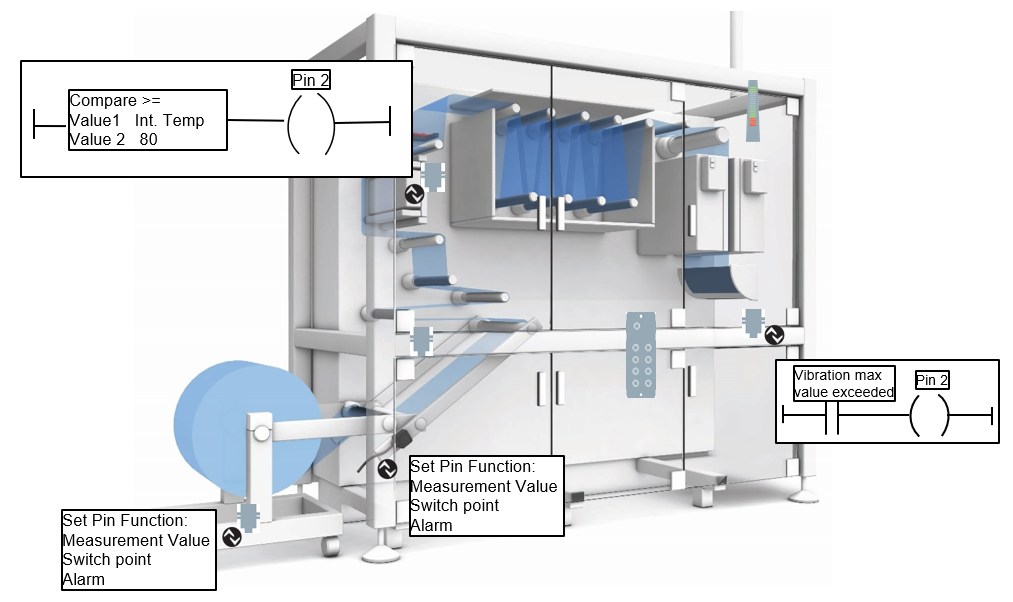

- In combination with the pin configuration in each SAMS device, the logic blocks also provide the option of responding to various alarms, even if the device is not used in an IO-Link topology. The result of a logic block can, for example, be output directly on pin 2 of the device and thus immediately switch on external hardware without delay. (Alarm relay, alarm signal horn, alarm light, …). Thus, a SAMS device can be used outside any IO-Link, fieldbus or even PLC topology and the user can still use the integrated additional information for condition monitoring.

- The programming effort in possible higher-level control units such as PLCs can be reduced by implementing logical functions of signals already in the device. This means less effort in programming. Plant engineers who use different control systems in their machines do not have to create one and the same logical function in the different control platforms again and again. The function is parameterized once in the device and can be used without restriction in the application, regardless of which higher-level control system is used.