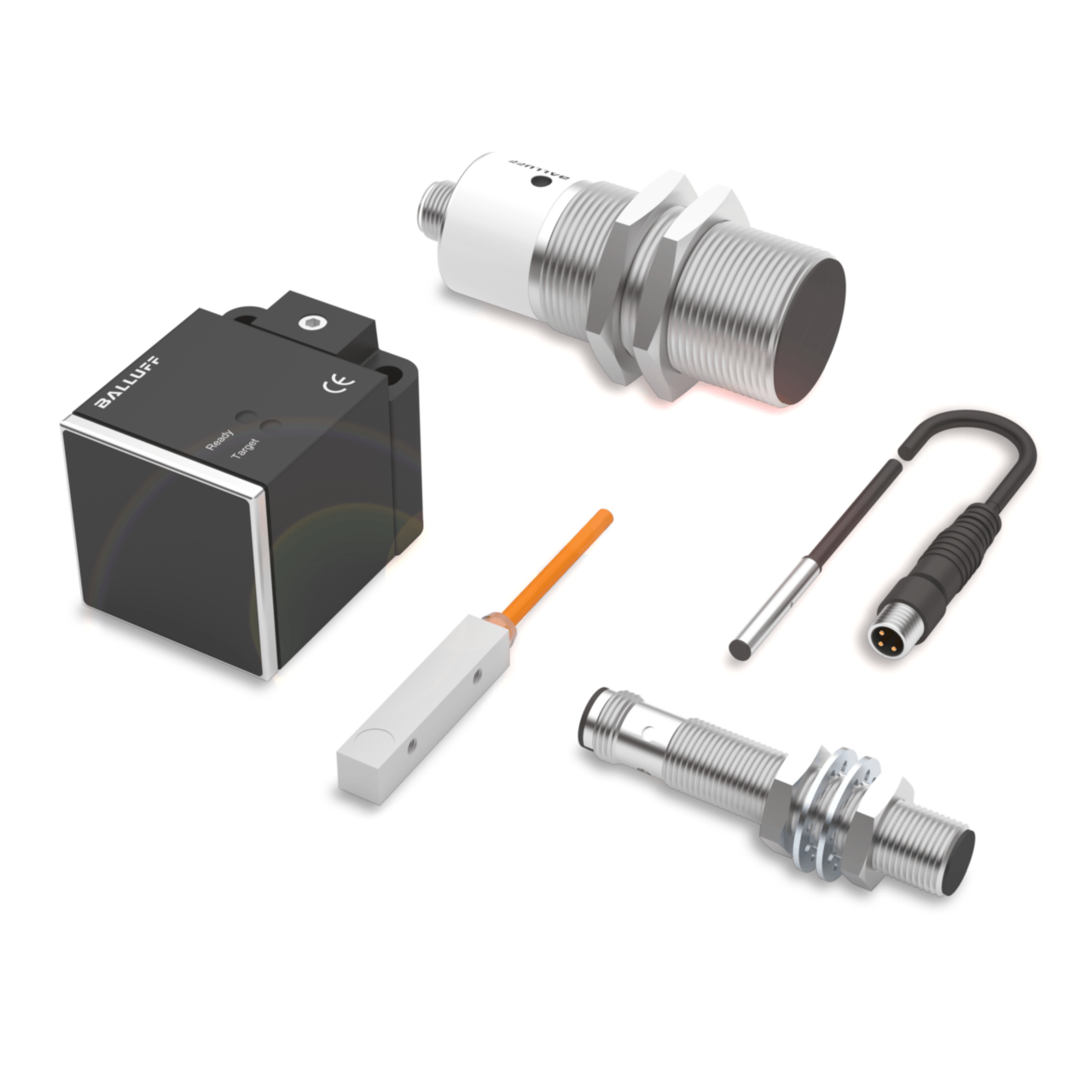

Inductive proximity switches and proximity sensors

Inductive sensors

Available in:

25 Series

Balluff offers a wide range of inductive proximity switches and sensors for various applications and industries. Whether standard inductive proximity sensors, high-pressure sensors, hygienic sensors / washdown compliant, factor 1 sensors, magnetic field resistant by magnetic shielding, weld immune proximity sensors, high temperature sensors, explosion-proof (IECEx, ATEX) or NAMUR sensors, you are guaranteed to find the right product for your individual application in our portfolio thanks to different housing materials and sealing methods. We offer different designs, housing diameters and thread sizes for easy integration in a wide range of situations and for optimum solutions even where space is limited.

The technology used worldwide has an optimum price-performance ratio and can be supplied in short delivery times, even for large quantities.

Increase the availability of your systems and reduce maintenance and storage costs at the same time with inductive proximity switches from Balluff.

Available special features of our sensors

- Plug or cable connection

- Cylindrical and various rectangular designs

- Variants for DC-3/4 wire, IO-Link and DC, AC and AC/DC-2 wire

- Flush and non-flush sensors

- Short and long designs with and without fixed stop

- Explosion proof proximity switches and sensors

- High-pressure-resistant sensors up to 500 bar

- High-temperature sensors up to 230 °C

- Hygienic sensors with high chemical resistance and a high degree of protection up to IP69K

- Magnetic field resistant sensors

- Weld-immune proximity switches and sensors

- Factor 1 sensors or NAMUR sensors

25 Series

| Series | Style | Range Sn max. | Switching function | Switching output | Connection type | Installation | Actions |

|---|---|---|---|---|---|---|---|

BES M SCylindrical version |

M18x1, M30x1.5, M12x1, M8x1 | 30 mm | normally closed (NC), normally open (NO), NO/NC | Push-pull, NPN, PNP, PNP/NPN/push-pull | Cable, Cable with connector, Connector | for flush mounting, non-flush, quasi-flush | |

BES G SCylindrical version without thread |

D3.0, D6.5, D8.0, D10.0, D4.0 | 5 mm | normally closed (NC), normally open (NO) | NPN, PNP | Cable, Cable with connector, Connector | for flush mounting, non-flush | |

BES M MCylindrical miniature version |

M4x0.5, M5x0.5 | 5 mm | normally closed (NC), normally open (NO) | NPN, PNP | Cable, Cable with connector, Connector | for flush mounting, non-flush | |

BES Q26 SSquare version with 26 mm height |

26x26 | 10 mm | normally open (NO) | polarized, PNP | Cable with connector, Connector | for flush mounting | |

BES Q40 SSquare version with 40 mm height |

40x40 | 40 mm | normally open (NO), NO/NC | NPN, PNP | Screw terminals, Connector | for flush mounting, non-flush | |

BES Q80 SSquare version with 80 mm height |

80x80 | 50 mm | normally open (NO), NO/NC | NPN, polarized, PNP | Screw terminals, Connector | for flush mounting, non-flush | |

BES Q MSquare compact version |

8x8, 5x5 | 3 mm | normally closed (NC), normally open (NO), NO/NC | NPN, PNP, PNP/NPN/push-pull | Cable, Cable with connector, Connector | for flush mounting | |

BES R SCubic version |

30x20x10, 50x25x10, 59x25x10, 30x10x6, 32x20x8, 16x8x4.7, 40x12x26 | 8 mm | normally closed (NC), normally open (NO), NO/NC | NPN, PNP | Cable, Cable with connector, Connector | for flush mounting, non-flush | |

BES M F1Factor 1 in cylindrical design |

M18x1, M30x1.5, M12x1, M8x1 | 20 mm | normally open (NO) | NPN, PNP | Connector | for flush mounting, non-flush | |

BES Q40 F1Factor 1 in square version with 40 mm height |

40x40 | 40 mm | normally closed (NC), normally open (NO), NO/NC | NPN, PNP | Connector | for flush mounting, non-flush, Flush on one side | |

BES R F1Factor 1 in cubic design with through-holes |

32x20x8 | 5 mm | normally open (NO) | PNP | Cable with connector | for flush mounting | |

BES M HTCylindrical version for temperature-resistant applications |

M18x1, M30x1.5, M12x1, M8x1, M5x0.5 | 15 mm | normally open (NO), NO/NC | NPN, PNP | Cable, Cable with connector, Connector | for flush mounting, non-flush | |

BES Q12 HTSquare version with 12 mm height for temperature-resistant applications |

12x12 | 4 mm | normally open (NO) | PNP | Cable | for flush mounting | |

BES Q40 HTSquare version with 40 mm height for temperature-resistant applications |

40x40 | 25 mm | normally open (NO) | for switching amplifier, PNP | Connector | non-flush | |

BES Q8 HTSquare version with 8 mm height for temperature-resistant applications |

8x8 | 2 mm | normally open (NO) | PNP | Cable | for flush mounting | |

BES M MFCylindrical version for magnetic-field-resistant applications |

M18x1, M30x1.5, M12x1, M8x1 | 20 mm | normally open (NO), NO/NC | NPN, PNP | Connector | for flush mounting, non-flush, quasi-flush | |

BES Q40 MFSquare version with 40 mm height for magnetic-field-resistant applications |

40x40 | 40 mm | normally open (NO), NO/NC | PNP | Connector | for flush mounting, non-flush, Flush on one side | |

BES R MFCubic version for magnetic-field-resistant applications |

32x20x8 | 7 mm | normally open (NO) | PNP | Cable, Cable with connector | for flush mounting | |

BES M PCylindrical version for high-pressure-resistant applications |

M18x1, M30x1.5, M12x1, M8x1, M5x0.5 | 40 mm | normally closed (NC), normally open (NO) | NPN, PNP | Cable, Cable with connector, Connector, Leads | for flush mounting, non-flush, quasi-flush | |

BES M FMCylindrical version with all-metal housing |

M18x1, M30x1.5, M12x1, M8x1 | 8 mm | normally closed (NC), normally open (NO) | NPN, PNP | Connector | for flush mounting | |

BES M HCylindrical version for hygienic applications |

M18x1, M12x1 | 8 mm | normally closed (NC), normally open (NO) | PNP | Connector | for flush mounting, non-flush | |

BES G EXCylindrical design without thread for potentially explosive areas |

D6.5 | 1 mm | Cable | for flush mounting | |||

BES M EXCylindrical version for potentially explosive atmospheres |

M18x1, M30x1.5, M12x1, M8x1 | 15 mm | normally open (NO) | PNP | Cable, Connector | for flush mounting, non-flush | |

BES Q40 EXSquare version with 40 mm height for potentially explosive atmospheres |

40x40 | 35 mm | Connector | for flush mounting, non-flush | |||

BES SPSpecial version |

2 mm | normally open (NO) | PNP/NPN | Connector | for flush mounting |

Edit columns

Please select which columns should be displayed.

Products

Products